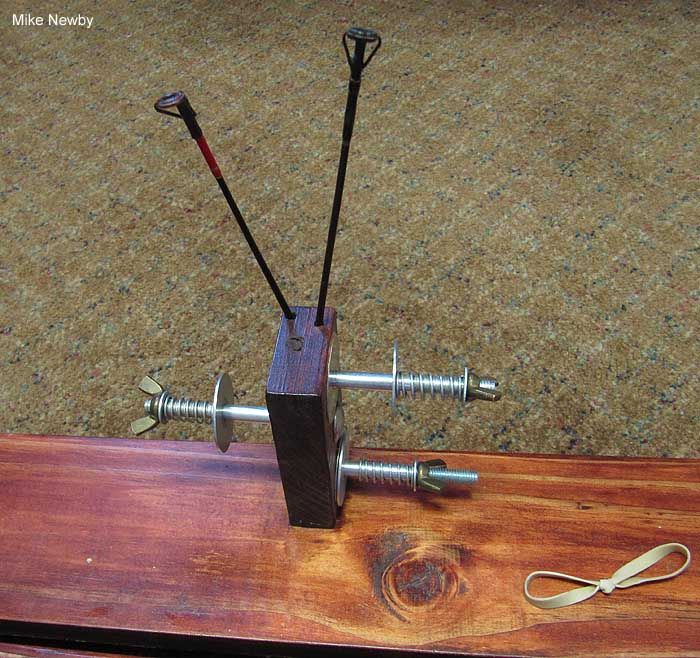

In the previous pic you'll see I drilled two holes in the top of the thread holder, at slight angles. That is for old rod-tips...I put those in, and the thread comes off the spool then, up through the rod-tips, and then down to the rod blank you are working on. This gives you good control over the thread tension should you move back a turn or so, plus provides the correct angle for the thread coming down to the blank, from the rod-tips. (You can even use piano wire (even better), and glue rod tips to it. Or very stiff wire, whatever...make a plan...as they say).

Another pic of the movable rod stands, and the track they move in:

DRYING STANDS:

I drilled holes through the sides of the cup, epoxied 8mm nuts to the inside, and then screwed in 8mm bolts, with rubber cups glued to the bolts ends. Then I could secure a rod by turning the bolts in. But, since then I don't use that method anymore...just put thick rubber bands on, and then slip the rod's butt through the centre. The rubber bands grip the rod butt securely and turns the rod. Works 100%. So you can just really glue a few dowels into the cup, to hold the rubber bands as shown.

a Hole is drilled right through the stand, and the mocrowave motor is secured to it, with it's shaft going through the hole.

I epoxied the microwave motor's table stand (that brown female ferrule jobbie that makes the table turn) to the plastic cup. Don't glue it onto the motor's shaft...just use prestik te secure it in. You want to be able to take it off, just in case. If you really want, you can glue it together...just know, that should the motor burn out (never happened to me yet, touch wood) you can remove the cup and replace the motor.

That's a very simple way to make drying stands. Make more than one seperate stand (I use two), then you can put the entire rod in the drying stand. The motor side holds the butt section, one seperate stand holds the centre of the rod just before the second rod ferrule, and then another seperate stand to hold the rod at the tip side.

When making these seperate stands, make sure the "V" in them lines up 100% to the centre of you motor's shaft, of course...so the rod is level when you have in in the set-up and drying.

) Can get from material shops

) Can get from material shops

Reply With Quote

Reply With Quote

Bookmarks